The CIM4.0 manufacturing demonstration lines solution is a training program populated with Industry 4.0 technology to educate students not only on how these components work but how they work together.With the focus on advanced manufacturing technologies and how they are integrated to deliver automated systems, theplatform is an ideal environment to delve into Industry 4.0 skills like advanced communication, Internet of Things, data analytics, and automation.

YORNEW and our industry partners are stepping up to deliver state-of-the-art training solutions for Industry 4.0. By augmenting skills training, introducing new areas of study specific to Industry 4.0.

Industry 4.0 introduces technology and capabilities that at the highest level take automated, manufacturing to the next level. Information collection and data analysis enable predictive maintenance, flexible manufacturing and efficient optimized factories.

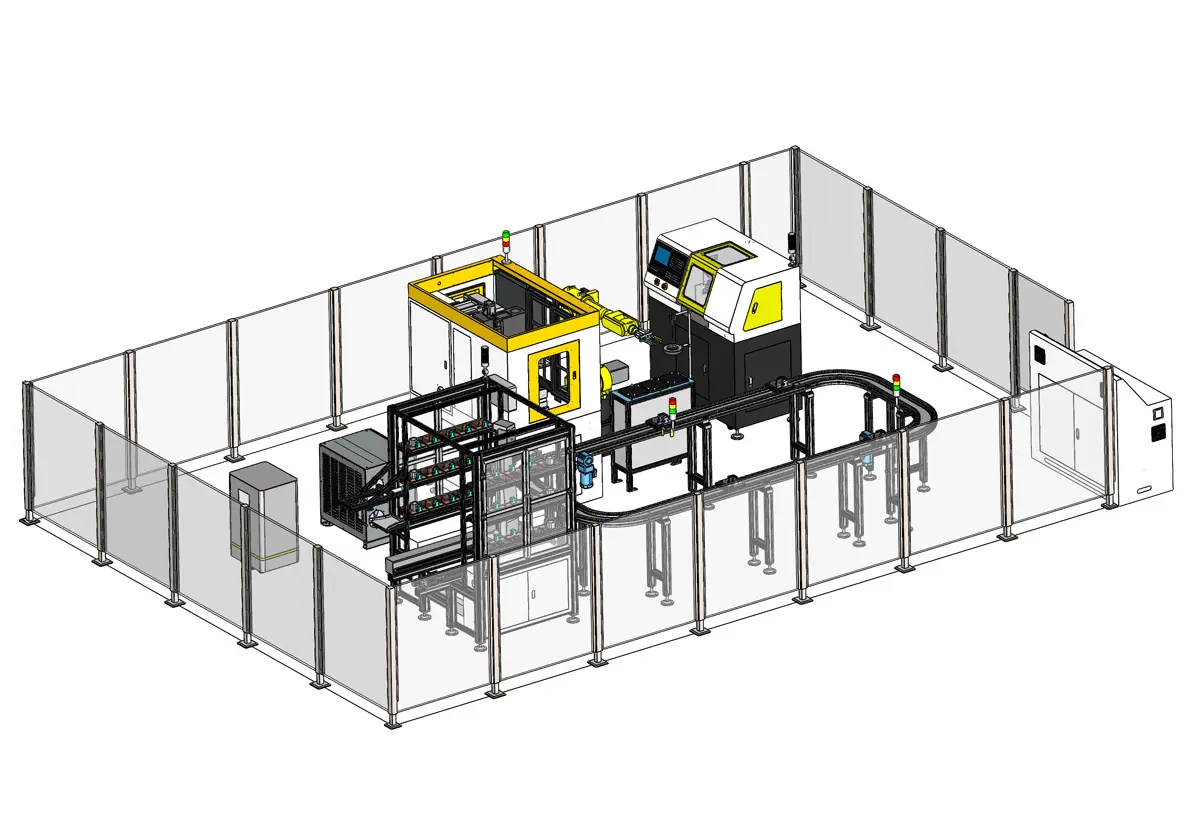

Yornew's CIM4.0 is an integrated, end-to-end manufacturing process with real industrial equipment capable of producing real products. The cell has all the components typical to state-of-the-art industry 4.0 factories and is used to train students of all levels about manufacturing and Industry 4.0 concepts.

Using the CIM project with a fully simulated industrial CIM, students learn about all the aspects of a CIM production cycle, from customer order and inventory control, through automated manufacturing of materials into finished parts, to quality inspection and final delivery, Students set up and operate CIM cells and learn about mass production, Uses real industrial hardware,including Industrial conveyor system links workstations,six axis robot,3-axis CNC mill machining,CNC lathe maching,ASRS(automated storage & retrieval station), AGV (automated guided vehicle), visual inspection,industry 4.0 sensors, networking and integration etc. Full size equipment from end to-end,manufacturing line produces real products. Our Industry 4.0 Education Solution are modular and flexible solutions for educating and training students in the principles and technologies of computer integrated manufacturing.

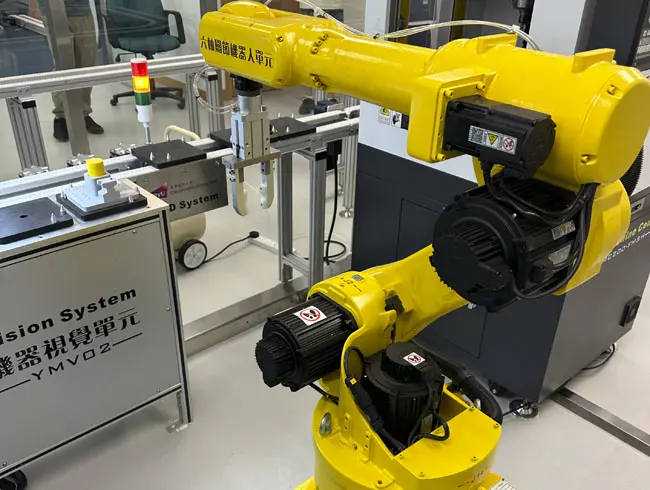

The floor-mounted six axis robot loads and unloads parts to and from the CIM conveyor,include loads and unloads CNC mill milling parts, CNC lathe turning parts,routing, AGV (automated guided vehicle), etc.

The ASRS system includes a dedicated 4 axis robot that transfers parts between storage cells and conveyor pallets. The ASRS is controlled and monitored from the central management console. The ASRS can include RFID, other inventory and location tracking devices.

The automated guided vehicle loads and unloads parts to automated storage & retrieval stationIt .It has two types navigation, options laser guided navigation and magnetic navigation.

The closed loop conveyor frame moves pallets carrying part templates (holders) that are loaded and unloaded at each station by robots and manipulators.

Robot loads part to small CNC lathe from the conveyor,can maching a variety of material, like aluminium, brass, plastic,wood, composite, and wax. The door open when maching finishes,robot unloads part to next station.

The 3-axis center's door auto open,robot loads part to 3 axis CNC center from previous station,can maching a variety of material, like aluminium, brass, plastic,wood, composite, and wax. The door auto open when maching finishes,robot unloads part to next station.

CIM4.0 is the latest generation of CIM systems delivered to educational institutions for advanced training.The system has been upgraded with many enhancements to ensure the components and the content is Industry 4.0 ready and student will learn to install, operate and use the new capabilities just as they may upgrade an existing production line.

The CIM industry 4.0 System is the core of the solution. It is a full-size manufacturing production line with stations designed to manufacture parts from raw material, assemble products and test them for adherence to quality control standards. Custom tailored to your needs,bespoke system design, modular and expandable, Each station is customizable and configurable,supports third-party components.This is a flexible model and can be constructed with more or less stations to suit the needs of the school and the program being installed,provide students with in-depth training on specific skills found in industry as well as the specific new skills related to Industry 4.0.